Stock Management

- Stock Reservation

- Cost Prices

- Stock Allocation

- Store Stock

- Stock Terminology

- Orphan Stock and Stock Matching

- Despatching Order Lines without Stock

Stock Reservation

Stock Reservation prevents automated processes from over-allocating a unit of stock

However, it is possible for a human to override this by manually selecting already reserved stock during Stock Allocation .

How Stock Reservation Works

Sales Orders

Stock which is allocated to a Sales Order line is always reserved to that Sales Order line.

Quotes

When creating a quote, the user will be asked if stock should be reserved for it. This stock will be reserved until the quote expires.

Draft Orders

Stock allocated to draft orders will never act as a reservation. If the user would like to reserve stock, the draft should be converted to an order.

eCommerce Baskets

Stock that is added to an eCommerce basket will be reserved for that basket for the duration of the user’s session. The reservation status will be automatically cleared one hour after the user becomes inactive.

Stock Locations

If a Stock Location is set toe 'reserved' then all stock in that location will be considered reserved, even though it is not linked to a Sales Order.

FAQs

What is Stock Reservation?

Stock Reservation is the process by which stock is reserved to Sales Orders.

How does this work with Purchase Orders?

A similar process is used with stock ordered via a Purchase Order.

Once stock has been ordered from a Supplier, and the stock has been

Can stock reservation be overridden?

Yes - it is possible to over allocate a single unit of stock. More information is available here.

Cost Prices

This page outlines the way in which Cost Prices are managed, both against individual units of stock, and directly related to Sales Orders.

The Basics

Cost prices are managed within the Variant Tab, and can also be amended within the CSV Import or by using the Price Management tool.

It is possible to set multiple Cost Prices for a single Variant if your system is enabled for Multiple Suppliers.

When stock is added to the system, it will be stored with a Cost Price. That will usually be based on the default Cost Price but may be adjusted in various ways (more detail below).

When fulfilling orders, IXO Commerce will always prioritise the oldest units of stock available.

Zero vs Null Cost Prices

When a product is created, the Cost Price will be set to 'null', unless a user actively amends it.

A 'null' Cost Price means that one has not been entered, and so IXO Commerce can not use it for any purpose. This includes, but is not limited to:

- calculating the total price of Purchase Orders (e.g. an error message will be shown)

- calculating the profit margin of an order (e.g. the unit of stock will be excluded, both as a revenue and as a cost)

- profit margin in reporting (e.g. the unit of stock will be excluded, both as a revenue and as a cost)

- stock holding (e.g. the unit of stock will be excluded from the report)

A 'zero' cost price of £0.00 must be manually entered. If it has been, this will be treated as an absolute value, and will therefore be used by the system as the Cost Price for that item. This includes, but is not limited to:

- calculating the total price of Purchase Orders

- calculating the profit margin of an order (e.g. that line would be 100% profit)

- profit margin in reporting (e.g. sales of that unit of stock would be 100% profit)

- stock holding (e.g. the stock holding for that unit of stock will be £0.00)

Stock Adjustments

Stock may be adjusted either through a Manual Stock Adjustment or via the Stock Take screen.

Manual Stock Adjustments

| Item | Details |

|---|---|

| Adjusting a Variant | When added, stock will be added to the system with a Cost Price that matches the default Cost Price for the Variant |

| Adjusting a Unique Stock Record | When added, stock will be added to the system with a Cost Price that matches the default Cost Price for the Unique Stock Record, if it is different to that stored against the linked Variant |

If your product is enabled for Multiple Suppliers and has multiple Cost Prices, when stock is added manually, IXO Commerce will use the lowest Cost Price as the default Cost Price.

Stock Take

| Item | Details |

|---|---|

| Stock Taking a Variant | When stock level is increased, stock will be added to the system with a Cost Price that matches the default Cost Price for the Variant |

| When stock level is decreased, stock will be deducted from the oldest stock records first | |

| Stock Taking a Unique Stock Record | When stock level is increased, stock will be added to the system with a Cost Price that matches the default Cost Price for the Unique Stock Record, if it is different to that stored against the linked Variant |

| When stock level is decreased, stock will be deducted from the oldest stock records first |

If your product is enabled for Multiple Suppliers and has multiple Cost Prices, when stock is added manually, IXO Commerce will use the lowest Cost Price as the default Cost Price.

Purchase Orders

When a Variant is added to a Purchase Order, that line is added at the default Cost Price set for that Variant.

If your product is enabled for Multiple Suppliers and has multiple Cost Prices, when a Variant is added to a Purchase Order, it will use the Cost Price linked to the Supplier attached to that Purchase Order.

Cost Prices may be amended within the Purchase Order.

If the cost price is changed on the purchase order after the stock has been received, it will update the cost price of the unit of stock.

The link to the purchase order is broken once the line has been despatched. If returned, the unit of stock will not be updated by changes against the purchase order.

Cost Prices and Sales Orders

Cost Prices are linked to Sales Order Lines, and are used for margin reporting throughout IXO Commerce.

Default Function

| Item | Details |

|---|---|

| Variants | By default, it takes the cost price of the variant as it was at the time the order was created. |

| If the default cost price of the variant changes, it does not affect existing sales orders. | |

| Unique Stock Records | If a Unique Stock Record exists and has been selected when creating the order, the default cost price of the Unique Stock Record will override the variant cost. |

Existing Stock

| Item | Details |

|---|---|

| Stock Assignment | If stock is assigned from a warehouse/stock location, it will take the cost price from the oldest unit of stock within that location. |

| If the order line is for more than one item, the oldest items in that location are allocated to that order line, producing an average cost price. | |

| The average cost price is calculated from the costs of the allocated units, as only one cost price can be stored per sales order line. |

Purchase Orders

| Item | Details |

|---|---|

| Order Line Allocation | If the order line is allocated/linked to a purchase order, the cost price on the purchase order will override the default cost price. |

| Goods In | When the stock item on the purchase order is received, a new unit of stock is created with a cost price that matches the purchase order. This item is then automatically allocated to the Sales Order. |

| Changes to Purchase Order | If the cost price is changed on the purchase order after the stock has been received, it will update the cost price of the unit of stock and, subsequently, the Sales Order. |

Practical Examples

Example 1: Assigning Sales Orders

- Order Creation:

- Variant "Widget A" has a default cost price of £10.00.

- Sales order created on 01/01/2024 uses this cost price.

- If the cost price of "Widget A" changes to £12.00 on 02/01/2024, the sales order from 01/01/2024 still uses £10.00.

- Unique Stock Record:

- Unique Stock Record for "Widget A" has a cost price of £11.00.

- When creating the sales order, this record is selected.

- The cost price for the sales order line is £11.00, overriding the variant’s default price.

Example 2: Existing Stock

- Stock Assignment:

- Warehouse location "Main" has 3 units of "Widget A" with cost prices £10.00, £11.00, and £12.00 (oldest to newest).

- Sales order line requests 2 units of "Widget A".

- The system assigns the two oldest units (cost prices £10.00 and £11.00).

- The average cost price for the sales order line is £10.50.

Example 3: Purchase Orders

- Linking to Purchase Order:

- Purchase order for "Widget A" has a cost price of £13.00.

- Sales order line is linked to this purchase order.

- The cost price for the sales order line is £13.00, overriding the default cost price.

- Changes and Despatch:

- Cost price on the purchase order is changed to £14.00 after receiving stock.

- The new cost price of £14.00 updates the unit of stock and the sales order.

- Once the sales order line is despatched, it no longer updates from the purchase order.

Example 4: Stock Adjustments

- Variant "Gadget B" has a default cost price of £15.00.

- On 03/01/2024, 5 units of stock are manually added via a Stock Adjustment.

- These units are now in the system at the cost price of £15.00, matching the default cost price at time of the Stock Adjustment.

Example 5: Stock Take

- Warehouse "North" has 10 units of "Gadget C" with varying cost prices.

- During a stock take, it is discovered that 2 units are damaged and removed from the system.

- The system deducts the 2 oldest units first, adjusting the average cost price accordingly.

Example 6: Multiple Suppliers

- Variant "Tool D" has cost prices from Supplier A (£20.00) and Supplier B (£18.00).

- A purchase order is created with Supplier B, setting the cost price to £18.00.

- When stock is manually added, the system uses the lowest cost price, which is £18.00.

FAQs

What happens if the stock is returned after despatch?

The link to the purchase order is broken once the line has been despatched. If returned, the unit of stock will not be updated by changes against the purchase order.

How do I view the cost price history of a variant?

Stock Allocation

Overview

Stock Allocation is the process by which a unit of stock is added to a Sales Order. This process can be manual or automated.

Stock Allocation is powered by Store Stock and Purchase Orders.

Automated Stock Allocation

If automated, IXO Commerce will allocate stock based on proximity and age. It will prioritize stock from the selling Store (e.g., the Store in which the Sales Order was created), and will always allocate the oldest units first.

If there is no stock available in the selling store, IXO Commerce will allocate stock from other stores, if available. Stock will be allocated from the location with the most available stock, although other settings at the Store and Location level may override this.

If there is not enough physical stock in the business, IXO Commerce will attempt to allocate stock from open purchase orders, if there is free stock on a purchase order.

If there is insufficient stock available (either in the business or in open purchase orders), then the order will fall into ‘unallocated’ and manual intervention will be required.

At minimum, the auto-allocation process will run hourly.

Manual Stock Allocation

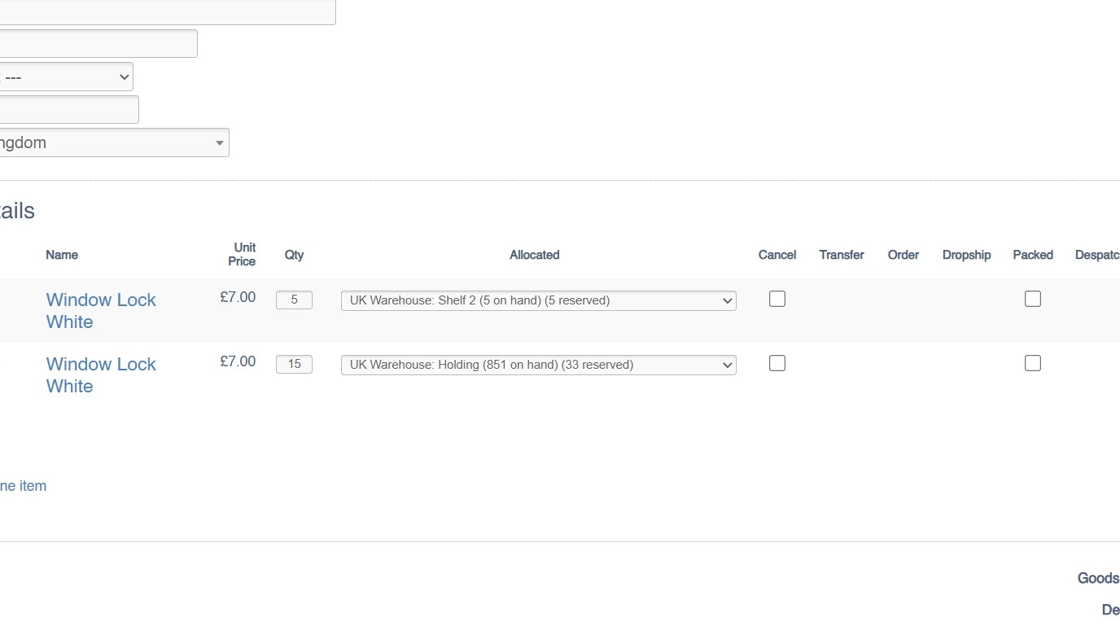

Manual assignment can either be done within the POS or from the Sales Order edit screen. The function is similar in both, but in the POS, it is not possible to split stock or to create new purchase orders.

Units of stock are displayed per Location/Purchase Order, with clear indicators for quantities On Hand/Reserved/On Order/Allocated.

For definitions on these terms, please see Stock Terminology.

POS Allocation

To allocate a line within the POS, the user must click or tap on the line item. This will open the edit item pop-up, and stock may be allocated using the drop-down.

Sales Order Edit Screen Allocation

To allocate a line within the Sales Order edit screen, the user simply uses the drop-down against the relevant Sales Order line.

Allocation Options

A user may either:

- Leave the line as ‘not allocated’ (this will trigger automated allocation processes) and flag the Sales Order Line to be shown in Required Orders if it meets the other criteria

- Mark the line as ‘do not allocate’ (this will prevent automated allocation processes) and flag the Sales Order Line to be shown in Required Orders if it meets the other criteria

- Allocate existing stock from a location by choosing a location

- If there is not enough stock in the location for a line, e.g., 5 are needed and location A only has 2, then a split stock button will appear. This will allow the user to split the line, so that the first part is fulfilled from location A, and the second part can be allocated separately

- Create a new purchase order using the tick box to the right of the drop-down. That will create a new back-to-back purchase order linked to this Sales Order line.

- New purchase orders may also be created from the Required Orders screen

- Stock Reservation prevents automated processes from over-allocating a unit of stock

However, it is possible for a human to override this by manually selecting already reserved stock during Stock Allocation.

Overallocation

A Sales Order Line may become overallocated for a variety of reasons. These include (but are not limited to):

- a stock take has reduced the amount of stock available in an allocated location

- a user has manually over allocated multiple orders to the same stock location

- fewer units than expected were received via a Purchase Order

It may also be that there is a Sales Order Line that can not be allocated as the quantity required is larger than the quantity available in any given stock location; for order lines like this, it may be necessary to treat it as an overallocation

Resolving Overallocation

This can be achieved via the Split Stock button on the Sales Order page:

1. This order is overallocated

2. Click "Split stock"

3. This will split the problematic Sales Order Line into two lines; this will retain the same price, date added, etc., in order to maintain reporting integrity

4. The lines will still be allocated to the same Stock Location, so you will need to change this using the Allocation drop down

5. Choose your new Location/Purchase Order

6. Click "Update items"

7. Repeat these steps if necessary

8. This will have resolved the stock overallocation

FAQs

How does automated Stock Allocation work?

IXO Commerce allocates stock based on proximity and age. It prioritizes stock from the selling Store and allocates the oldest units first.

Can I rely solely on automation?

No, if there is insufficient stock available, the order will fall into ‘unallocated’ and manual intervention will be required.

Is it possible to over allocate?

Yes - within the CMS a user may assign the same unit of stock to multiple Sales Order Lines. This will result in over allocation (see above).

Store Stock

Stores and Locations

In IXO Commerce, stock is managed at the Store level, with each Store potentially having multiple Locations.

Each Location can be set to one of the following statuses:

- Available: Stock is available for order fulfillment.

- Unavailable: Stock is not available for Sales Order fulfillment (typically used for damaged stock).

- Reserved: Stock is reserved and cannot be used for Sales Order fulfillment.

Units of Stock

For each item (e.g., a Variant or a Unique Stock Record), there may be multiple units of stock. These units are organized by:

Date Received: When the stock was added to the system (typically the date it was received on a Purchase Order)

Cost Price: The cost to associated with that unit of stock.

This allows for multiple units of the same item to have different cost prices and dates of receipt.

Adding Units of Stock

Units of stock can be created through:

- Manual adjustments

- Stock take

- Purchase ordering

Removing Units of Stock

Units of stock can be removed through:

- Manual adjustments

- Stock take

- Supplier returns

- Sales Order fulfillment

Practical Examples

Example 1: Multiple Units of Stock

- Storing the age of a unit of stock:

- Variant “Gadget A” has 5 units of stock in the Bristol Store

- 2 units were received on the 01/05/2024

- 3 units were received on the 24/02/2024

- Storing different Cost Prices:

- Variant ‘small-pink-shirt’ has 5 units of stock in the London Store

- 1 is stored at a Cost Price of £5

- 3 are stored at a Cost Price of £6.50

- 1 is stored at a Cost price of £7

- Total value of the stock holding is £31.50

Example 2: Stock Adjustments

- Variant "Gadget B" has a default cost price of £15.00.

- On 03/01/2024, 5 units of stock are manually added via a Stock Adjustment.

- These units are now in the system at the cost price of £15.00, matching the default cost price at time of the Stock Adjustment.

Example 3: Stock Take

- Warehouse "North" has 10 units of "Gadget C" with varying cost prices.

- During a stock take, it is discovered that 2 units are damaged and removed from the system.

- The system deducts the 2 oldest units first, adjusting the average cost price accordingly.

FAQs

Can I have units of stock with multiple cost prices for the same item?

Yes, IXO Commerce allows you to manage multiple units of the same item with different cost prices and dates of receipt. This helps in accurate cost tracking and inventory management.

Will units of stock be linked to Purchase Orders?

Yes, if a unit of stock was ordered and received as part of a Purchase Order, the Purchase Order Id will be stored alongside the cost price and date or receipt.

What happens if stock units have different dates of receipt?

IXO Commerce allows you to track the date each unit of stock was received, which helps in identifying the age of your stock and managing stock rotation effectively.

Stock Terminology

Current Stock

This list applies to units which are currently in the business. These terms are used throughout the CMS and the POS.

| Label |

Purpose |

| Stock |

Total number of units in the business

Includes Available, Reserved and Unavailable |

| On Hand |

Number of units held at the current Store

Includes Available, Reserved and Unavailable |

| Available |

Number of units available for Sales Order fulfilment in the User's current Store

This equals On Hand minus Reserved and Unavailable |

| Reserved |

Number of units Reserved to Sales Orders and eCommerce baskets

Includes all Sales Order lines which have not been despatched, and excludes orders with the following statuses:

Also includes units of stock in locations marked as 'Reserved' |

| Unavailable |

Unavailable units, typically damaged or undergoing quality control

Number of units held in locations marked as 'Unavailable' |

| Available Elsewhere | Number of Available units elsewhere in the business, e.g. the total amount of Available units in other Stores |

Purchase Orders

This list applies to units which are currently on order from a Supplier. These terms are used throughout the CMS and the POS.

| Label | Purpose |

| On Order |

Total number of units ordered from the Supplier

Typically, this is in relation to the total number of units ordered from a Supplier on a particular Purchase Order

This equals 'Allocated' plus 'Unallocated' |

| Allocated |

Total number of units on a Purchase Order allocated to Sales Order lines

This equals 'On Order' minus 'Unallocated'

This figure includes units on 'Locked' Purchase Orders |

| Unallocated |

Total number of units on a Purchase Order that are free to be allocated

This equals 'On Order' minus 'Allocated'

Units on a 'Locked' Purchase Order will be excluded from 'Unallocated' |

POS

This list includes labels which are only used within the POS.

| Label | Purpose |

| Available to order | Signifies that there are no units of the SKU within the business, and that there are none on order - fulfilment of a new Sales Order will only be possible following a Purchase Order |

| Backorder lead time is xxx days | Displays the default lead time for the SKU |

eCommerce

This list includes labels which are only used within the eCommerce website.

| Label | Purpose |

| In Stock |

Signifies that there are units available in the business, and that a new Sales Order may be immediately fulfilled

An 'In Stock' figure is made up of the total number of Available units in Locations across all Stores enabled for web fulfilment. |

| Out of Stock |

Signifies that there are no units available in the business, and that a new Sales Order may be will not be fulfilled

An 'Out Of Stock' figure is determined by checking the total number of Available units in Locations across all Stores enabled for web fulfilment. |

| Available (allow XXX days for delivery) | Displays the default lead time for the SKU |

| Low Stock |

Signifies that there are only a small number of Available units

Triggered if the number of 'In Stock' units is less than the 'Low Stock (order at)' figure on the Inventory tab |

| Available to pre-order |

Signifies that stock is coming into the business, which will be used to fulfil a new Sales Order

The appropriate lead time will be displayed in the checkout

Only displays if 'allow back order' is not enabled

Total number of units available to pre-order equals the total amount of 'unallocated' units for that SKU across all Purchase Orders |

Orphan Stock and Stock Matching

Orphan Stock

Orphan stock occurs when a unit of stock becomes disassociated from its original purchase order. This can happen in several ways, such as manual stock adjustments made through the inventory screen or the addition of new stock during a Stock Take. Another common issue arises when non-existent stock is dispatched—if that stock is later returned, it remains unlinked to any purchase order, further complicating inventory tracking.

Orphan Stock Cost Price

Whenever units of Orphan Stock are created, they will inherit the default cost price for that Variant or Unique Stock Record.

Example 1

A customer has bought a Red Hat. There are no stock records for the Red Hat, but Bob has found one. He packs up the item and marks the order as despatched.

The Sales Order is not linked to a Purchase Order, so the true cost of the item is not known.

The Cost Price of the Variant as of today is £5.43, so £5.43 is recorded against the Sales Order and is used in margin reporting.

Example 2

In IXO Commerce, Shelf A has 5 Blue Hats that arrived on PO123 at £2.34 each.

During Stock Take, those are not found, and the stock is removed. At the same time, Shelf B is found to have 5 Blue Hats, so these are added.

If there was no link to another stock record, those new ones would be added at today's cost price of £3.45.

Automated Stock Matching will automatically resolve this problem (see below)

Stock Matching

IXO Commerce will attempt to match Orphan Stock Records as best it can, in order to reduce their number. This will occur in a few specific cases:

- If adjustments are made within a week of each other, for the same SKU

- If adjustments take place within the same store

If automatic Stock Matching is not possible, it will still be possible for a user to manually amend the Cost Price of Orphan Stock Records via the Inventory tab.

Example 1

A customer has bought a Red Hat. There are no stock records for the Red Hat, but Bob has found one. He packs up the item and marks the order as despatched.

The Sales Order is not linked to a Purchase Order, so the true cost of the item is not known.

The Cost Price of the Variant as of today is £5.43, so £5.43 is recorded against the Sales Order and is used in margin reporting.

There is no matching adjustment, so nothing can be matched automatically.

Example 2

In IXO Commerce, Shelf A has 5 Blue Hats that arrived on PO123 at £2.34 each.

During Stock Take, those are not found, and the stock is removed. At the same time, Shelf B is found to have 5 Blue Hats, so these are added.

Because these Stock Takes took place within a week of one another, IXO Commerce can update the Orphan Stock Records with Purchase Order and Cost Price information; the Stock Records on Shelf B will be linked to PO123, and their cost price will be set to £2.34.

Despatching Order Lines without Stock

It is possible to dispatch line items without stock, either through the POS or via the CMS (order detail screen).

POS

A user may manually mark a line as despatched; they are also despatched when Completing an order.

A system setting is available to prevent dispatching items without stock in the POS.

CMS

It is always possible to despatch without stock from the CMS Sales Order screen.

Reporting

If a Sales Order line is despatched without stock, an entry will be made in the Stock Discrepancy report.

FAQs

Why allow despatch of items without stock?

In most cases, businesses want to tightly control stock levels so that only available inventory can be sold or dispatched. However, there are practical situations where allowing dispatch without stock is not just useful, but necessary:

- Stock Accuracy Issues – Real-world operations sometimes suffer from stock discrepancies (miscounts, damaged items, or delays in stock updates). If the system blocks dispatch completely, it can halt order fulfilment unnecessarily, even when the item is physically available.

-

Urgent Customer Needs – In retail or wholesale, meeting a critical customer deadline may be more important than stock accuracy. Dispatching without stock lets the business complete the order and correct the stock position afterward.

- Operational Flexibility – Some businesses prefer to allow managers (via the CMS) to override stock restrictions when exceptional circumstances arise. This gives control to responsible staff while maintaining normal safeguards at the POS.

Why allow wouldn't I despatch items without stock?

-

Stock Accuracy & Integrity

If items are dispatched without stock, the system no longer reflects reality. This undermines the accuracy of inventory data and makes it harder to trust reports. -

Overselling

Allowing dispatch without stock increases the risk of selling products that cannot actually be fulfilled, leading to customer dissatisfaction or cancelled orders. -

Financial Misreporting

Inventory valuation and cost-of-sales reporting rely on accurate stock records. Dispatching without stock can create gaps that distort financial reporting. -

Operational Confusion

Staff may assume goods are available when they are not, leading to errors, wasted time, and additional administration to fix discrepancies later. -

Loss Prevention & Control

Strict stock controls help prevent misuse, theft, or mistakes. Allowing dispatch without stock can weaken those safeguards.