Stock Allocation

Overview

Stock Allocation is the process by which a unit of stock is added to a Sales Order. This process can be manual or automated.

Stock Allocation is powered by Store Stock and Purchase Orders.

Automated Stock Allocation

If automated, IXO Commerce will allocate stock based on proximity and age. It will prioritize stock from the selling Store (e.g., the Store in which the Sales Order was created), and will always allocate the oldest units first.

If there is no stock available in the selling store, IXO Commerce will allocate stock from other stores, if available. Stock will be allocated from the location with the most available stock, although other settings at the Store and Location level may override this.

If there is not enough physical stock in the business, IXO Commerce will attempt to allocate stock from open purchase orders, if there is free stock on a purchase order.

If there is insufficient stock available (either in the business or in open purchase orders), then the order will fall into ‘unallocated’ and manual intervention will be required.

At minimum, the auto-allocation process will run hourly.

Manual Stock Allocation

Manual assignment can either be done within the POS or from the Sales Order edit screen. The function is similar in both, but in the POS, it is not possible to split stock or to create new purchase orders.

Units of stock are displayed per Location/Purchase Order, with clear indicators for quantities On Hand/Reserved/On Order/Allocated.

For definitions on these terms, please see Stock Terminology.

POS Allocation

To allocate a line within the POS, the user must click or tap on the line item. This will open the edit item pop-up, and stock may be allocated using the drop-down.

Sales Order Edit Screen Allocation

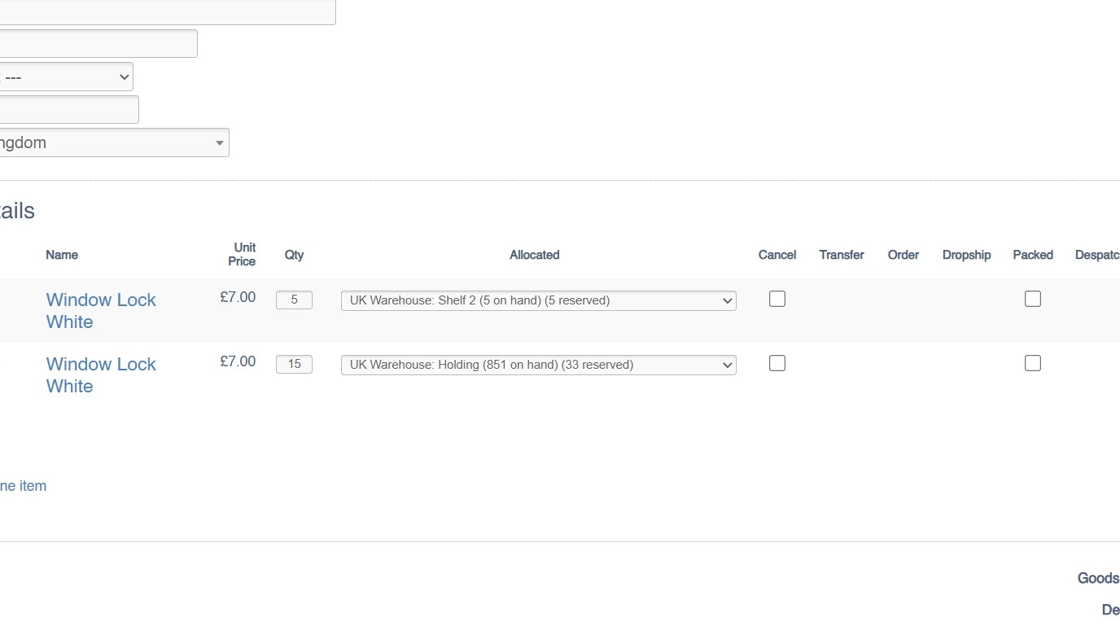

To allocate a line within the Sales Order edit screen, the user simply uses the drop-down against the relevant Sales Order line.

Allocation Options

A user may either:

- Leave the line as ‘not allocated’ (this will trigger automated allocation processes) and flag the Sales Order Line to be shown in Required Orders if it meets the other criteria

- Mark the line as ‘do not allocate’ (this will prevent automated allocation processes) and flag the Sales Order Line to be shown in Required Orders if it meets the other criteria

- Allocate existing stock from a location by choosing a location

- If there is not enough stock in the location for a line, e.g., 5 are needed and location A only has 2, then a split stock button will appear. This will allow the user to split the line, so that the first part is fulfilled from location A, and the second part can be allocated separately

- Create a new purchase order using the tick box to the right of the drop-down. That will create a new back-to-back purchase order linked to this Sales Order line.

- New purchase orders may also be created from the Required Orders screen

- Stock Reservation prevents automated processes from over-allocating a unit of stock

However, it is possible for a human to override this by manually selecting already reserved stock during Stock Allocation.

Overallocation

A Sales Order Line may become overallocated for a variety of reasons. These include (but are not limited to):

- a stock take has reduced the amount of stock available in an allocated location

- a user has manually over allocated multiple orders to the same stock location

- fewer units than expected were received via a Purchase Order

It may also be that there is a Sales Order Line that can not be allocated as the quantity required is larger than the quantity available in any given stock location; for order lines like this, it may be necessary to treat it as an overallocation

Resolving Overallocation

This can be achieved via the Split Stock button on the Sales Order page:

1. This order is overallocated

2. Click "Split stock"

3. This will split the problematic Sales Order Line into two lines; this will retain the same price, date added, etc., in order to maintain reporting integrity

4. The lines will still be allocated to the same Stock Location, so you will need to change this using the Allocation drop down

5. Choose your new Location/Purchase Order

6. Click "Update items"

7. Repeat these steps if necessary

8. This will have resolved the stock overallocation

FAQs

How does automated Stock Allocation work?

IXO Commerce allocates stock based on proximity and age. It prioritizes stock from the selling Store and allocates the oldest units first.

Can I rely solely on automation?

No, if there is insufficient stock available, the order will fall into ‘unallocated’ and manual intervention will be required.

Is it possible to over allocate?

Yes - within the CMS a user may assign the same unit of stock to multiple Sales Order Lines. This will result in over allocation (see above).